Conveyor drums

Conveyor drums

Conveyor drums are one of the most important industrial tools for transportation and handling of various types of appliances, products and packaging that are produced and designed in different forms. It can be used for loading, in petrochemical, steel, pharmaceutical, border ports for unloading and loading, airports, automobiles, mines, etc. An important part of these conveyors are drums. Drum or Conveyor drums are important pieces. A conveyor drum must be customized or pre-prepared by companies and prepared according to customer’s requirements. Of course, in many cases, there is a need for design from zero.One of the most important points about buying conveyor drums is paying attention to the structure of the type of rubber cover and the combination of rubber materials for rubber coating.

If you want to buy conveyor drums or rollers, you need to have some background information on how to determine its authenticity and quality. However, this product, like any other material, is marketed with different characteristics and characteristic. The method of making, the type of metal used and how to assemble it on the shaft and what type of steel or alloy in the shaft, such as ST37 or MO40 or CK45 steel, etc. even affects the price. Conveyor drums are placed at the beginning and end of this mechanical structure which can also be electronic. In rollers, there are a series of components that we will be more familiar with.

What are Conveyor drums?

Conveyor drums are an important piece that has a driver structure. A particular type may be used in any of the conveyors you see, acting just like a tyre for a car. Its rotation causes the mechanical system to carry out transport and freight operations. In fact, the movement of this device is done by drums.

In each Conveyor drum, we are faced with a few key and main components that will include:

1. The main body and frame of Conveyor drums

2. Conveyor’s end shaft

3. Roller cap or pulley

4. Rubber conveyor coatings

5. Bearing

6. Conveyor drums walls

Turning process of making rollers:

In the operation of lathes on rollers depending on the dimensions of the shell (pipe) the lathe machines (heavy lathe or conventional lathe) are used, which depends on the diameter and length of the pipe. For better adhesion of rubber coating on the surface of rollers, turning operations are performed on the surface of the roller shell.

If needed, you can download roller catalog.

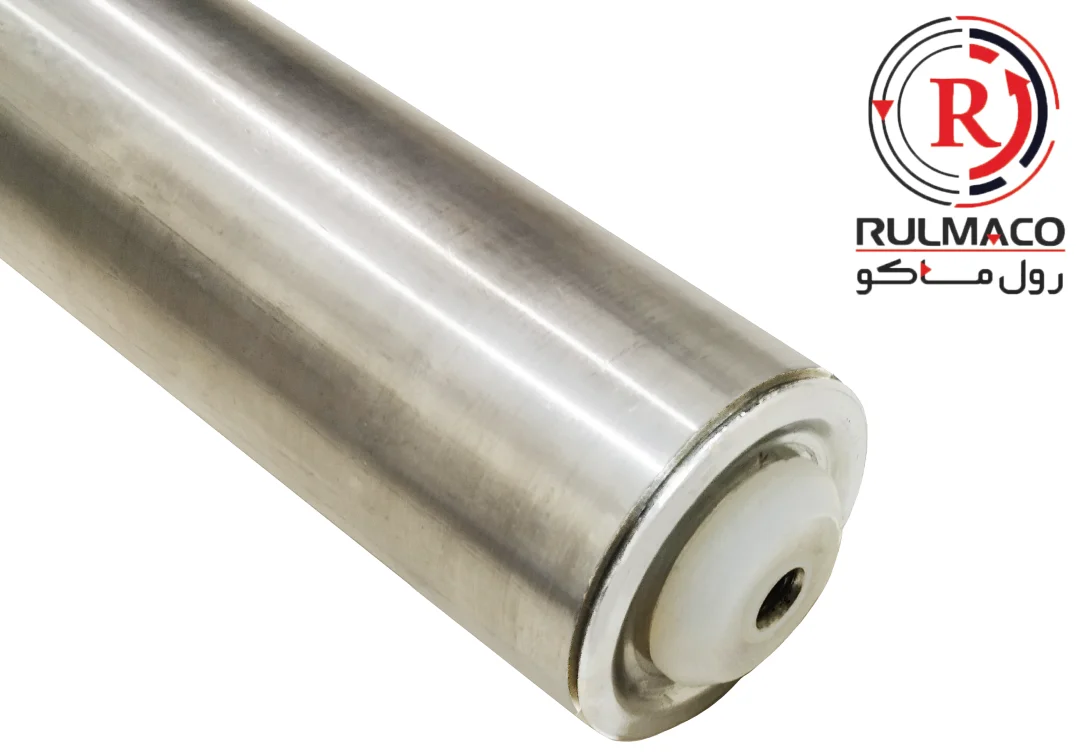

Roller Shaft

Shafts are made as a main piece in the form of metal-based rods. Of course, this material in technical and mechanical definitions is different from what we will refer to, but ultimately global shafts are placed from the beginning to the end of rollers and are used to transfer power or torque in an electronic devie. It’s similar to a rod in terms of appearance as mentioned. The diameter of the rod will also be determined according to the customer’s requirements or the type and scope of his application.

This shaft is less in some samples and in some cases more used.

The shaft in an industrial device will have a rotational motion that will transfer power from one device to the secondary. Regarding the quality of Conveyor drum shafts, it should be said that ultimately this section is made based on two types of materials:

Alloy Steel CK45

Another type is known as CK45 steel, which can be used in projects that require larger Conveyor drums. CK 45 steel is suitable for medium-sized parts with higher dimensions (heavy blacksmithing parts) and more complex shapes in automotive manufacturing and machine engineering (such as ship shafts, transmission parts, wheel hubs). The lowest operating temperature is -25 °C, the optimum creep behavior will be up to 480 °C.

CK45 steel with an average carbon content of 0.45 percent is classified as medium carbon steel, which is one of the most widely used non-alloy carbon steels in international standards. Its most important advantage will be reasonable price and resistance to corrosion and rust. In many cases, it is possible to make Conveyor drum parts with this material.

Steel st37

It is a soft steel equivalent to AlSl 1045 with a chemical composition of 0.8% manganese, 0.5% C, 0.3% Si plus other elements with a hardness of 170 HB and tensile strength of 650-800 (N/mm2) in general. St 37 steel can be used directly without heat treatment unless special use is required.

The ST37 is a low carbon steel with a maximum carbon ratio of 0.20 despite the low cost, the softest hot rolled steel. In general, the main advantage defined for this product will be its low price. Heat treatment can be performed on it and due to its mechanical properties and metallurgical properties, it is widely used in industries and mines. Conveyor drum shafts are also made of this material, which will make the final price lower.

Upside-down caps

Inverted caps also cause nothing to penetrate into the rollers and the dust does not cause it to become disabled over time. The closure of these doors also prevents the protection system from falling and getting stuck inside them.

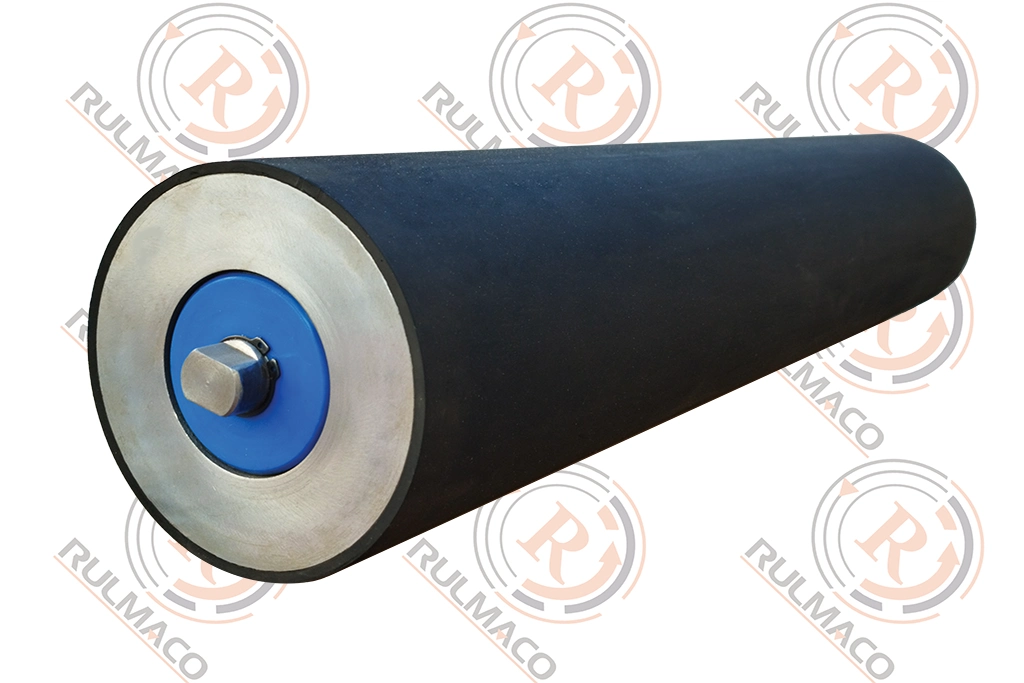

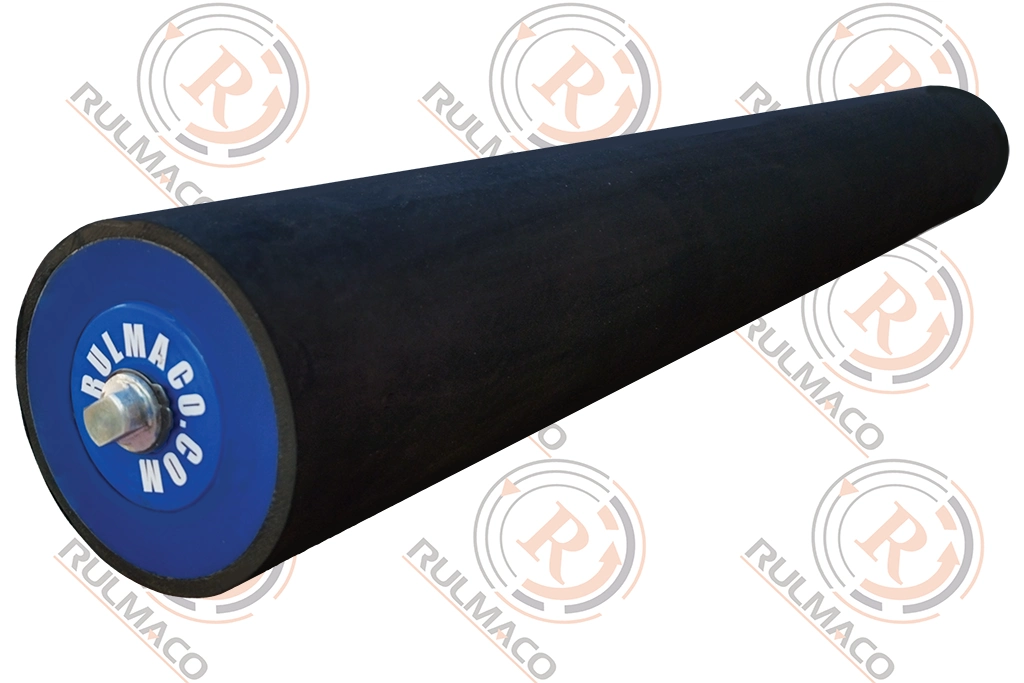

Rollers rubber coatings

Another requirement for the construction and design of a roller and a high-quality conveyor system is the use of coatings that are drawn as integrated tapes on metal (pipes) or rollers surface. These coatings are based on various materials on the market.

In the first place, these tires are expected to have high resistance to corrosion, wear and exhaustion and mechanical fatigue. This resistance is calculated based on the hardness rate. The number is expected to be between 65 and 70. It is also essential that these tires are coated on pipes in the form of lozenge and with a thickness of 10, 15, 20 or even 25 mm depending on the customer’s requirements. This coating makes the drums first and foremost a proper and standard structure and can also be used in different domains.

Of course, it is not possible to make conveyor belts without using this material. Rubber coatings can be made of:

- Nitrile rubber or NBR

- NR Rubber

Built and used in these systems.

NBR

This material is a type of rubber that has high resistance to abrasion, corrosion, penetration of gases as well as high and low temperatures. Good resilience is one of its most important advantages. This rubber is used in the manufacture of a variety of coatings for Conveyor drums. Its thermal resistance is far better than other samples. It is commonly used in the manufacture of fuel pumps and all kinds of seals. Moving wheels and rollers are also made on the same basis.

NR

In contrast to the construction of conveyor drum veneer, NR tires are seen with exceptionally high strength and resistance to tearing and corrosion. Damping of this material is low and its resistance to dynamic fatigue is the main advantage seen in this product. It can be easily used in the temperature range of -70 to 120 °C. Natural Rubber Sheet or NR rubber has elasticity, expansion power and excellent compressibility. Electrical conductivity and abrasion resistance are also ultimately the most important thing that convinces you to choose it to make the coating.

How to connect rubber coatings to Conveyor drums

After we have met two popular materials to connect a coating layer on the conveyor belts, we need to provide you with information about how to link them. Generally, the following methods will be used to do this:

• Cold method

• Hot method

Cold method

The cold method is that by using a glue, the binding field of rubber materials is provided and finally with the same special adhesives are pressed coldly on the surface of the pipe, of course, in this condition, it is probably anticipated that the quality of the drum is much lower than expected. It is likely that soon this layer coating will be removed from the metal surface. Of course, the price of coating in a cold way is much cheaper.

Hot method

The secondary method is the use of hot method which is done through autoclaves. These devices can use heat and pressure just like an iron. In this case, the rubber completely sticks to the metal and gains tremendous resistance to heat or even cooling and scratching, etc. This will be done based on the use of an adhesive on the pipe, the connection based on pressure and heat, and finally steam. Although the price is higher than the cold method version of the veneer, it has a much higher quality.

Method 3: Hot pressing method

There is a third method which has been specifically established by Rulmaco Company for the first time that pipes and coating materials are placed in a specified form, just like a frame inside a thermal and compressive characteristic. Finally, the press machine at a certain heat and pressure can perform pasting operation to very good quality.

Finally, the drum will be removed from under the press machine and the coating will be fully ready. It can be said that this is a kind of hot method and the use of an innovative method even with higher reliability than the hot method.

Contact our experts and buy your suitable conveyor drum.

- Sales Manager: +989124944547

- Central Office : +982165465939

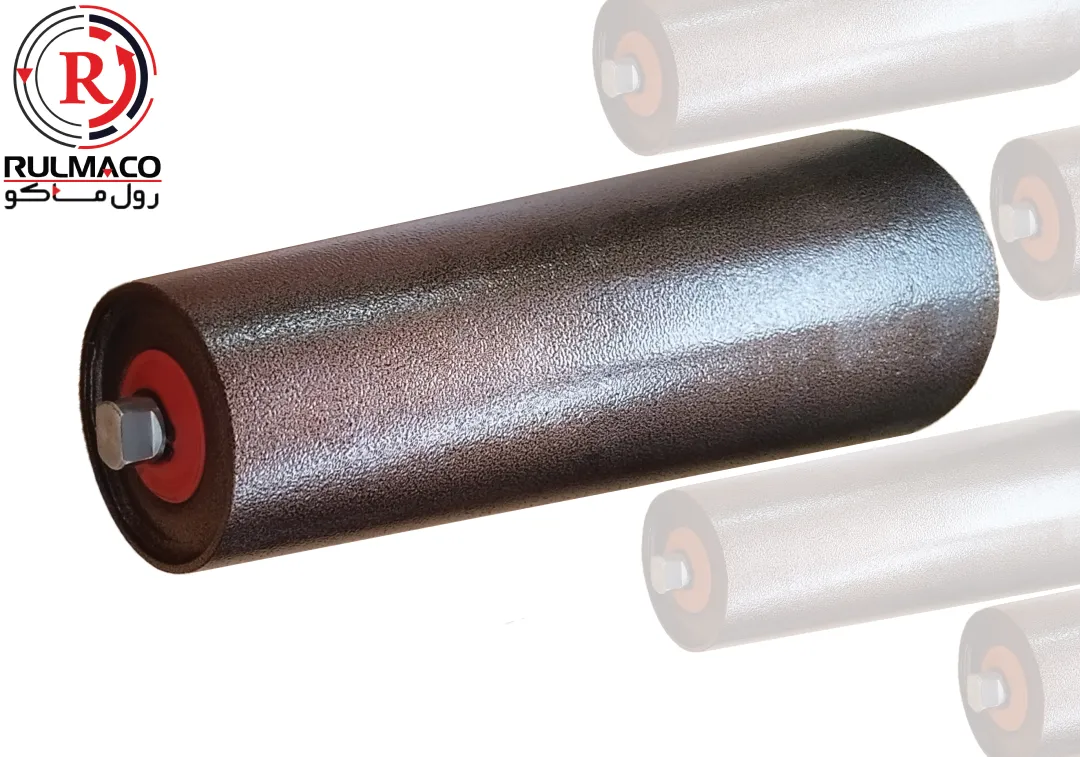

Conveyor drum walls

St37 sheets or similar materials can also be used in the construction of conveyor drum walls. Of course, it is still possible to customize this piece according to customer’s requirements, but it is essential that these walls be prepared based on the standard thickness, which can be used 7, 8, 10 cm or even higher. It is necessary to use up-to-date welding standards in their connecting operations and this process is fully specialized to attach the sheets to the pipes in the form of walls.

Finally, the important issue with the drum body is to show high resistance to corrosion, acid, etc.

Bearings

Bearings are also used depending on which type of conveyor or roller is used. Bearing is a roller bearing that performs three main functions while facilitating movement: carrying loads, reducing friction and placing moving parts of the machine. Bearings use ballks to separate two movement paths to reduce surface contact and friction between moving plates. This principle is very important in the case of conveyor drums because sometimes due to the pressure and motion rate it is necessary to use bearings.

Lockers on conveyors

Conveyor locker is an important and practical piece that can be prepared based on both a series of maps and ready-made materials and can be prepared based on sheets and pulleys that are available in the market as standard. Resistance to stresses and pressures of conveyor belt, design based on mechanical engineering and the possibility of weight control are among the most important points that should be taken into consideration when purchasing this piece.

If you want to buy lockers, it is necessary to pay special attention to the diameter of the conveyor shaft, the maximum torque rate of the electric motor, the maximum bending at the moment, and the axial force. In fact, in simple terms, the lockers are designed on the flat surface of the shafts without reacting only through friction operations, which prevent movements in situations of need for limitation.

Types of Conveyor drums based on installation method

The installation of conveyor drums is considered based on welding and replacement shaft methods. In drums that have a weld structure, the shaft will be welded to drums or pulleys. As a result, it is not possible to replace it without separating the welded material, but in contrast to the shaft to the drum with the possibility of replacing it just like a screw is embedded. The advantage of switching conveyor drums is that after a while of use in case of any problems, it can be easily disassembled and replaced by another drum. On the other hand, weld conveyor drums have a much lower price.

In fact, the main difference between these drums is the possibility of replacing or assembling them, which should be done by technicians in particular. The price of conveyor drums will be decisive in this case. Of course, the amount of load and pressure that is applied to the rollers can ultimately lead to decisions about this.

Tips on keeping and repairing roller drums

After purchasing roller drums, the important issue you should pay attention to is the correct maintenance and repairs. Choosing the right diameter is the first condition for extending their lifespan. You should also pay attention to the performance and thickness of the belts in order to choose the right diameter. Usually, factories have tables to compare thicknesses, number of layers, etc. according to which you can buy these belts and conveyors.

In order for your drums to stay healthy longer, plastic or rubber covers need to be used. Covered drums have higher corrosion resistance than metal type and will not damage the materials that are supposed to be transported with these systems. Their erosion is also much lower, so you can open a special account on these examples.

Rollers, vectors, actuator rollers, drum engines, motorized pulleys, belt cleaners, coatings, impact rods are among the most important components that are used in the manufacture of motor systems for mechanical activities, which are ultimately known as conveyors in Iran.

The application of conveyor belts is to transfer objects from point A to point B with minimal effort. The speed, direction, curvature and size of the conveyor belt vary according to the user’s requirements. In some industries, conveyor belts carry and remove products through production line or packaging.

The efficiency of conveyor belt systems helps to improve productivity, saves on labor costs and reduces delivery time. Basically, the conveyor belt is a very large broad belt that resembles a large rubber band, which forms a ring attached to the rotors that are connected to the rollers by an engine. Regardless of the materials used to produce conveyor belts, all types are designed to transport products, materials, appliances and parts efficiently and smoothly from one point to another.