What is a conveyor roller and what is its use ?

Conveyor roller is one of the main and most important equipment used in factories and manufacturing companies. You’ve probably seen various types of conveyor belts in TV shows of industrial and manufacturing centers. In fact, we are faced with random circles that rotate continuously on an axis and enable movement in a quasi-flat space.

The price of the conveyor belt, its construction quality, as well as the thickness, diameter and type of material are among the most important factors that should be paid attention during the purchase process. We try to move the article in a direction to be more a selection and purchase guide. Of course, we will mention some explanations about how this useful and important piece in mechanics was created.

Roller conveyors are a set of rollers housed in a frame that objects can be moved by hand, gravity or power on them. There are a wide variety of ways that roller conveyors can be used for a variety of applications including shipping crates, cartons, boxes, pallets, plastic bags, metals, sensitive and hands-free handling, boards and trays. Before getting familiar with the general definitions of what a tape roller is and what it is used for, let us first discuss what a roller is and what role it plays in the industry.

What is roller?

Rollers are one of the main and key components in any factory and the most important part of a conveyor belt. If you don’t know what a conveyor belt is, we will help you get to know this concept a little more basic. In fact, conveyor belts are the movement systems that work in factories in front of the managers or workers and allow the movement of a product or package during their rotation. One of its examples can be seen flight control buildings and airports gates where luggage and items move on it. This material causes movement of a surface just like an escalator.

Rollers are like a circular weight. They move in one axis and usually one of the most important points about buying a conveyor roller is their dimensions and size. As you may have noticed, they have a wide range and come in different series. The rollers are easily placed on the conveyor and with their rotational movement, they create a flat and rotating space. Rollers can be prepared in different dimensions and diameters according to various industrial and service needs.

Roller conveyors are commonly used in environments such as warehouses or manufacturing facilities due to the nature of goods transportation.

The use of roller conveyors can add versatility to the type of transfers, diverters and stops that can be used as part of a conveyor system or automation system. You can get roller conveyors made of mild steel, stainless steel, galvanized or plastic.

Contact our experts and buy your suitable conveyor belt

- Sales Manager: +989124944547

- Central Office : +982165465939

- Email : rulmaco.company@gmail.com

How does the conveyor belt work?

Therefore, conveyor rollers are an essential part of conveyor belts. In response to the question, how does the round weed or roller conveyor work? As explained above, the conveyor roller is responsible for supporting the conveyor belt. Since the conveyor belt rotates around the pulleys in an endless loop, the conveyor belt has an outer section and a return section.

To properly understand the function and performance of conveyor rollers, we first identify a number of components of a conveyor belt. It starts at the feed point where the material is poured onto the belt. The purpose of the conveyor belt is to transport the material to the discharge point where the material is again discharged from the belt. The outer part of the conveyor belt moves with the material from the feeding point to the discharge point and is called the upper or carrying part. The bottom or return part without material returns from the discharge point to the feed point.

Standard design ( an important factor)

Since the design of these conveyors is simple, many improvements have been done to allow roller conveyors to keep up with industry trends. The biggest innovation is the live roller conveyor or drive, which each roller is connected to a motor via a belt/chain/shaft to increase controllability.

This equalizes the speed of movement of materials along the rake path and also allows these conveyors to be used in reverse mode indefinitely, from low to high. They can work well in bi-directional applications because the rollers can move the material in either direction by changing the direction of the motor. In the following sections, we will look at the different types of electric roller conveyors because many types are suitable for use with a wide range of materials.

Types of rollers available in the market

The rollers available in the market are offered in different ranges according to the scope of application and design because companies’ need are different according to weight, condition and control mode. Regarding this topic, we should mention the issue of the conveyor roller’s application scope, which of course we will talk about in detail later. The most important thing you should know about the types of conveyor rollers is that these mainly metal pieces are divided according to the shape of the body, diameter, thickness and also the scope of application.

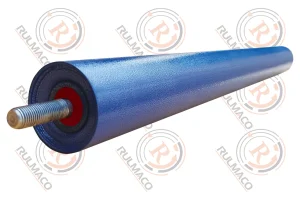

Polymer roller

Other models that are used in certain industries these days are known as polymer conveyor rollers, and the most important advantage about them is that they do not corrode materials softer than metal when they come into contact with them, especially in factories for transporting ceramic, tile, cement, and petrochemical industries. … This option is a common choice. One of the most important features of polymer rollers is reducing electricity consumption in industries and also the best option for areas with high humidity.

Reciprocating rollers

This model of roller conveyor is one of the most common and widely used options on the market. The roller is used to bear the weight on the conveyor belt and has a side surface to distribute the weight on the conveyor belt. The return model is also used to bear the weight in the conveyor belt, but it is used in the lower levels. Perhaps the most important issue regarding the difference between the conveyor roller in the two reciprocating models is the location and the tolerable incoming weight rate.

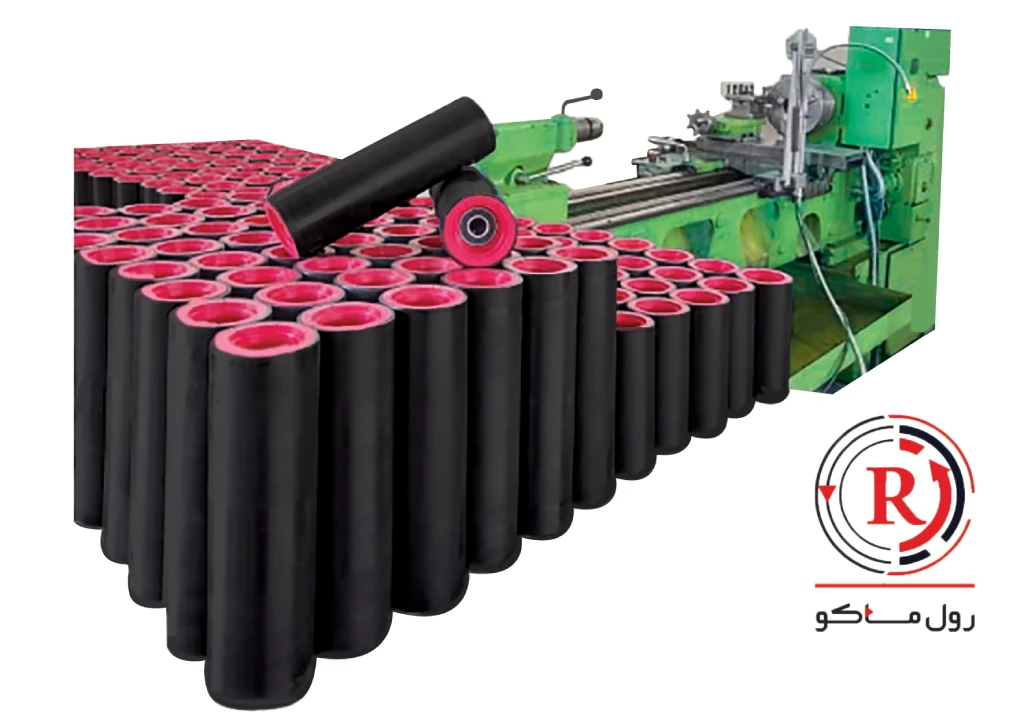

Press and normal rollers

There is another category for conveyor rollers. Normal and Press rollers are the cheapest models. In fact, if you intend to buy a cheap conveyor roller, it is a more suitable option considering the bearing used in it. New bearings will be used in Press models, and of course, they have more working power, technical durability, and longer life.

Today, Press rollers are one of the most used and can withstand a lot of weight in transport systems. This series of rollers are produced in 60, 76 and 90 Mm models or even more. They are one of the main choices in industries and mines.

replacement rollers

These rollers can be customized and the bearing on them can be changed. Of course, the customer can determine whether to use second-hand or new bearings; Another important thing about this product is that it has a surface that prevents dust from entering.

Metal rollers

Metal rollers are somewhat flat, but not as flat as steel. It is one of the best options in transmission systems. Their pipes are produced in factories and finally welding is done. Of course, the metal conveyor roller also shows high resistance against corrosion and oxidation although Its resistance to impact and pressure is slightly lower than that of the replacement roller.

Types of rollers based on body type

Similarly, there is another category for the conveyor roller, which will be based on the body type and construction material. Generally, steel and metal bases are used to make conveyor rollers. Therefore, it can affect the price issue. Some metals have higher resistance to oxidation and corrosion and are definitely a better choice for long-term use.

Aluminum roller

Finally, the aluminum conveyor roller is one of the best and most resistant options available in the market, which, of course, has a high price. The important thing about this roller is that it is rust-proof and does not return color, of course, choosing the type of body and the type of material used to make the conveyor roller is a key and specialized issue that should be chosen in consultation with people in this field.

Stainless Steel rollers

Stainless steel models are made with stainless material containing amounts of chromium and zinc. It is supplied as a replacement and press models, and the most important characteristic about them is that they show the highest resistance rate against corrosion, oxidation and rust. Also, the key factor about conveyor belt rollers is that they are reasonably priced and have excellent weight endurance.

Cast iron rollers

Cast iron rollers are also a good choice in terms of technical durability. Cast iron basically shows good durability against corrosion, heat and impact. Usually, the conical model conveyor roller is made of this material and its price is better than metals.

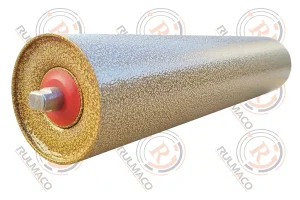

Teflon polymer rollers

Teflon and polymer materials are much better options for use in tile and ceramic factories and food industries. They do not create a lead structure and also provide the necessary condition from the hygienic point of view. Microbial cultivation and growth in the polymer conveyor roller is much more limited, so they are considered an excellent choice in food factories.

Guide roller

Conveyor belts are guided by guide rollers. Compared to other models in the market, they have a lower price, and of course, their type of use is also more limited.

The most important applications of the conveyor roller

Roller conveyor belt systems are used in various fields due to their wide application in many industries including transportation as well as packaging.

The following sectors are among the most important users of conveyor roller types:

Transportation of food and all kinds of industrial products, pharmaceuticals, etc., packaging and transportation from warehouses in factories and companies, baggage transportation in airports and flight terminals and train stations, steel industries and transportation of all kinds of heavy metal-based materials in factories and finally automobile factories

If we want to explain this more precisely, we can say that currently any company, industrial unit, factory and system that needs continuous transportation and this transportation terminal is inside a unit can use these tapes.

What are the advantages of using roller conveyor?

The roller conveyor is a practical and useful tool because it uses the earth’s gravity to transport goods and does not require human labor. It does not consume a lot of energy, and on the other hand, you can send a product from destination A to other destinations and several destinations with the lowest cost and also using a mechanical structure. In addition, the cost of roller tapes is much lower than other options and they do not cause any damage to the environment.

One of the key and most important points about these rollers is the low cost of maintenance and repair. They are usually usable for a long time, and in case of failure, you can turn them into a usable device again by replacing small parts and levers.

The unique structure and the possibility of making it in different diameters and thicknesses with different weight bearing capacities are also among the most basic issues that make the range of use of these devices go from carrying small cans to heavy cars and galvanized sheets in a completely flat way. There is almost no specific weight limit in the selection of these rollers, even in large factories producing steel materials, these mechanical devices are used.

Important points about buying a conveyor belt

If you intend to buy a conveyor roller, you have probably searched many websites or contacted several centers. One of the most important and key issues regarding the selection of conveyor rollers is attention to quality factors. Many domestic manufacturing companies and foreign factories operate in the field of manufacturing these materials. Some of them adhere to the quality and some others usually use a low-grade material to make these rollers. Anyway, we felt it necessary to talk about the key points that you should pay attention to in order to buy this product.

Attention to technical specifications

In the topic of choosing and buying conveyor belt rollers, one of the most important elements is to pay attention to the features and characteristics. Usually, in the production of this product, pipes are used, which can be galvanized, steel, etc. It is logically expected that the standard thickness limit be used. This issue will make these rollers bear enough weight and be able to maintain their resistance.

The first necessary specifications will be the materials used to make the frame and rollers. The frame is usually aluminum or steel, but it depends on the load on the surface and the capacity of the frame. Rollers are much more versatile in terms of composition because they come into direct contact with your product and can affect its behavior as it moves.

Some rollers are coated with plastic or rubber to increase friction, while others are simply aluminum or steel drums. Choose a roller that will keep your product in line and will not negatively affect the integrity of your product. Similarly, choose a frame that can support the weight of the material being transported as well as the weight of the rollers.

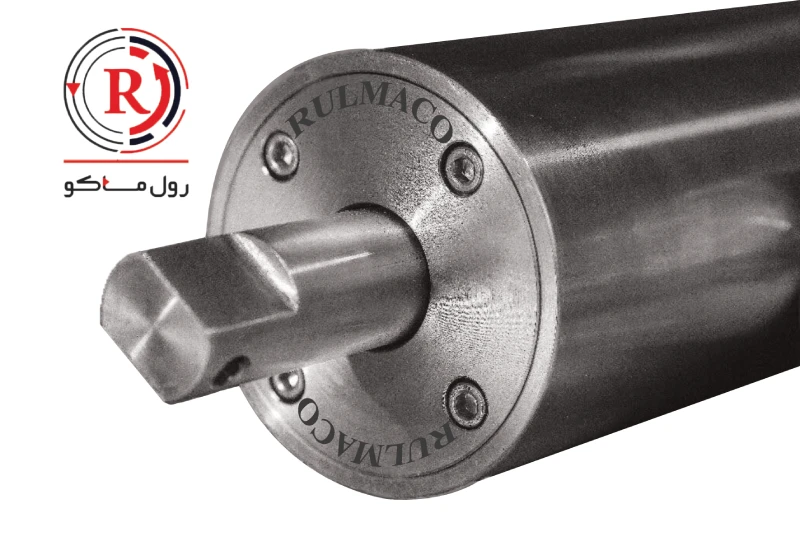

Using standard bearings

One of the most important elements in the construction of a conveyor roller is the bearing. It controls the movement and sliding structure, and if it is a replacement type, it is naturally a better choice. Also, after some time, the bearings gradually lose their quality and will definitely not be usable, so it is necessary to replace them easily.

Standard welding and turning

Another important issue in the discussion of the quality control of the rolls is to pay attention to the cutting method and also the welding resistance on the patches. If the patches do not have the necessary quality, the rollers will become disintegrated after some time. On the other hand, it is necessary that the spring used in this material has the necessary flexibility and does not get crushed due to the weight.

Load type and weight range

The type of load and weight depends on the transported product. What is the weight of the product? Is it fragile or can it come into contact with other items in the path? The answers to these questions will reveal more details about what type of roller conveyor will be useful. Gravity roller conveyors are optimal for smooth-bottomed, light-to-medium-weight objects such as boxes, bags, and jewelry, but should not be used to transport very delicate and rigid geometries, such as electronics and manufacturing components.

Behavior with goods, controlling factors and environment

Finally, you should consider the desired movement of materials, the amount of control and the environment in which the conveyor will work. If there is excessive heat, dust, dirt and moisture, choose a rougher design such as a chain conveyor roller. If precise timing and zero pressure are required, check out the high-tech roller conveyor options that give you the precision you need. If you just need a quick, low-tech way to move an object from point A to B, you may need to look no further than traditional gravity or roller conveyors.

Price commensurate with quality!

The final principle that you should be sensitive to when buying this product is the price. The price of conveyor rollers is determined based on the material of the body, thickness and diameter and the type of application. If they do not have the necessary quality, they can easily get damaged after a while. If the price is very low, it is possible that the manufacturer of the conveyor belt used low-quality materials.

Attention to the manufacturer of industrial rollers – principle 4+1

The last factor that is of course related to this topic, but in the final discussion is considered an important feature and is very important, will be paying attention to the manufacturer’s brand and the factory that produces the conveyor roller. Iranian and domestic companies should generally obtain the necessary permits from the ministries related to production and industry. BS-GIS-FEM-AFONE-DIN-ISO-CEMA are among the most important standards in this field. As a result, if you intend to check the price of the roller and its quality control, be sure to keep these conditions in mind.

The last step: how to prepare the conveyor belt roll?

The condition of quality, price and fast delivery is very important since the factories mainly take orders for the production of this product. Currently, Rulmaco Industrial Group is one of the main producers of various types of polymer rollers and metal rollers in the Iranian market, with long-standing experience and the use of knowledge-based expertise and science. Currently, in three main stages: request registration, production and development, and launch, Romak Sanat Enteghal company allows you to prepare various types of conveyor belts in wide applications.

These products are used in industry, mines, cement factories, transportation, ports and shipping, factories and production centers, and pharmaceutical and automotive industries. Rollers are one of the main and most important components of the industry and a key part of the European industrial revolution, which are still used in various factories.